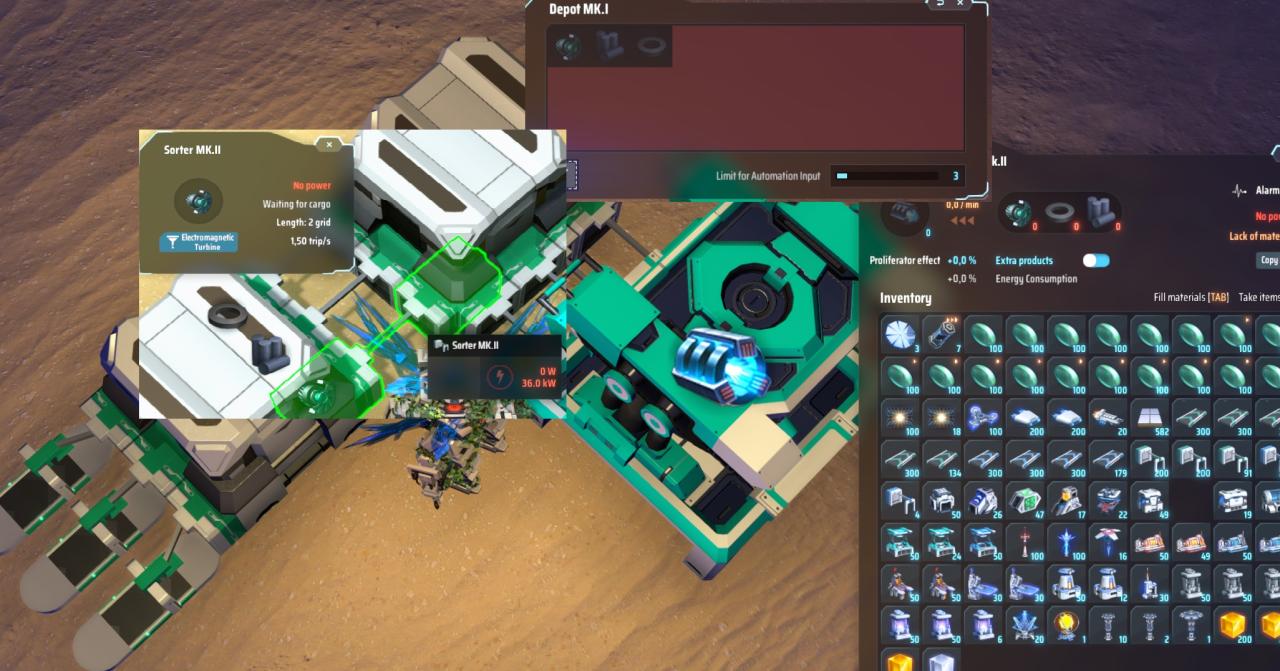

The Dark Fog update added a new feature to the game. Being able to filter the contents of boxes to an individual slot level. That opens up a new set of possibilities when it comes to item transportation due to ist physical nature in the gameworld.

They can be stacked and their contents can be made available instantaneusly over the space it occupies, meaning its width of 3 and its lenght both the small and big box make items available not only in one dimension but in three. X and Y we already have you might say and you are right, with some belt trickery we can cross belts or use splitters. Or we just use faster sorters to overcome the debuff of a sorter being slowed the further it has to travel to reach a belt.

This method is not worse or better than belts since it does have pros and cons. The update is very new and I just started to explore the new methods. What makes sense and what doesn’t the dos and don’ts essentially.

And I am here to try and explain the mechanics and requirements of such a bus system.

And spoileralert, there is even a hybrid version, but first you need to understand the new boxes itself to make use of that, so skipping to that might not help you a great deal.

The box Elevator

My favourite method is certainly a small box on a splitter. It does not need a sorter, or is limited by the sorters speed nor does it need power to operate.

Its main use serves as a buffer, for minersfor example doing two things at once, balancing the output of different miner speeds and providing a buffer that serves as additional storage when the miners can’t keep up with the belt speed.

What is new is that we can set individual filters for each slot, 30 in the case of the small box and 60 for the big one.

How does this help us you might ask, and the answer is not immediately obvious, because it strays into the territory of a frowned upon theory of transportation.

The mixed belt or sushi belt. That type of transportation always had an appeal but a major flaw. If transportet items do not consumed and stopped at the end of a belt the can brick the system.

The same was true for boxes without filters since we did not have control how much ends up in a box. If one item type was fed in too fast it might happen that other item tyes were not even present in the box.

We can control that now. That is the big difference. And it opens up possibilities very few have thought about before I imagine.

Limits for automation go hand in hand with the new change, as the box bus system has a major flaw with does not make it very appealing for lower ressource runs.

The system buffers. Alot.

The Rules of Insertion

A pillar of stacked boxes is sort of a Schrödingers Inventory. It is both individual boxes but it also is just one inventory with no walls inbetween.

What that means becomes obvious when I describe whats happening in the next picture.

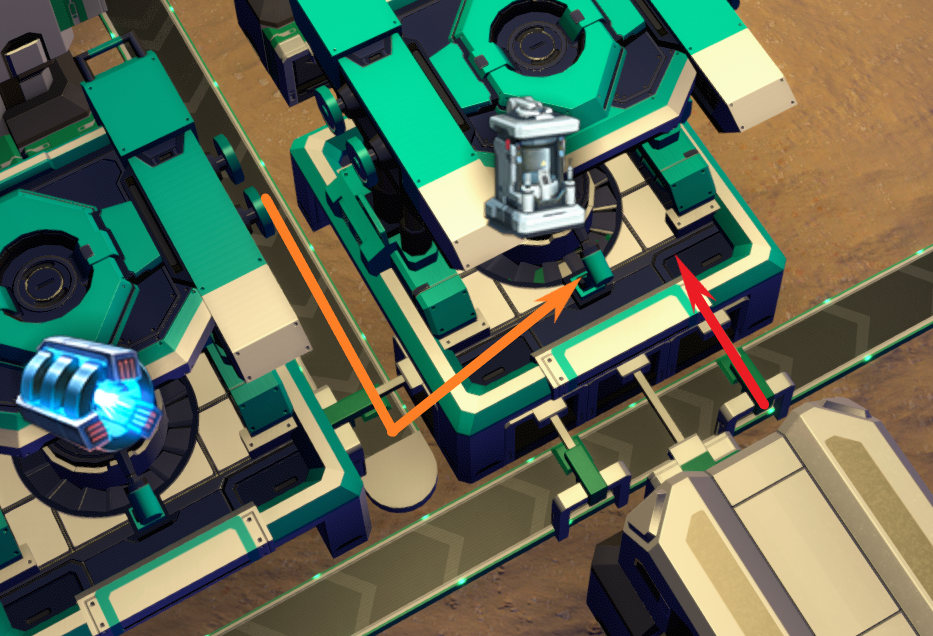

Rule # 1

On the left you see a sorter putting yellow cubes into the pillar. The pillar is 3 boxes high and the lower two boxes have their automation completely disabled.

The top box has a filter set for yellow cubes, and the sorter happily goes to work and fills that slot.

Conclusion: Insertion on the bottom to a filtered slot above it works.

On the right you see the opposite example. A sorter on the top tries to put yellow cubes into a pillar.

In this example the top two boxes have their automation disabled and the bottom box has a filter set for yellow cubes.

But this will NOT work. I don’t know why, and maybe it is a bug. I built a very intricate machine before, a very big one with the things I understood and had some of these cases present and it took me a while until I figured this particular detail out.

A very important one when it comes to something that uses alot of verticality, which you can see in the blueprints I will provide.

Rule # 2

This one is a follow up and a fix for the fail that happens on the right side. Unless it is the bottom box you want to set a filter in that box at that level you are inserting. In the example it will be fixed if I set the top right filter to yellow cubes. Thustly I can also remove the filter from the bottom box.

And I really really want to do that, because any filtered slot in that pillar will act as a buffer which will consume more ressources in the first start up. The buffer also enacts a different behaviour from a belt fed factory but that fun fact I will mention later.

Limitations and Preparations

I described that boxes can move items up. But you are probably asking, how do they come down.

The answer is simple. Anything that is in that pillar of boxes can be pulled out by a sorter on any level. And almost instantly after it is put in.

For example an item put into the top left most side of a 7 box high tower can be pulled out on the bottom on the right, regardless of the sorters speed since it does not have to travel over a grid.

In that case that item got teleported not just along the X axis along a belt but also in the Y and Z.

And since we can have multiple different items thanks to filters now that effectively crosses belts not just in a single planar dimension like X and Y where we use half height bridges and splitters to switch lanes, no the Z enables us to change the height in an efficient and beautiful manor.

Yes people use weird exploitative twisted belts, but who really wants that ugliness. And it also cannot travel diagonal in 3 dimensions.

Now you might think fiters! YEAH lets fill the boxes up with 30 different items and go banana!

And thats where I have to slow you down. We come to our first limitation. When travelling a box matrix network we can only transport 3 types of items through the box.

And there is a very specific reason for that. This also brings me to the other word in the title. Preparation. As per Rules of Insertion, there are rules that apply to taking things out that build upon inserting, because it is the same sorter that does the job.

Each sorter between boxes needs a filter. But don’t despair, its not as difficult as you think when you have a workflow which I will also try to expalin my thinking and where I start.

And let me explain why filters and what that means for the limit of itemtypes. When travelling along a bus the sides of boxes face each other. There are 3 ports present.

The way sorters pull items out of a box has an order. All sorters without filters pull from the bottom row and from the right of any items present.

Lets assume we have gears and processors in or box, full stacks. And filters set for the box also we want to put our gears and processors in. The box we want to put in our stuff has no gears but 95 processors. The box we want to pull out has 50 gears and 50 processors.

We use blue sorters which each can grab 6 at a time, and it just so happens that they are synced and work in the exact tick. Now each sorter will grab 6 processors because they are below the gears in the box.

But there is only room for 5 in our box. So what happens? All sorters go out having 6 cpus in their “hand”. One manages to put 5 in and still has one. The others still hold all 6.

But now the sorters will not go and put these CPUs back into the original box and grab gears. No.

These sorters will sit there holding their CPUs until the end of time.

And they will never be free to grab any gears and our machine is bricked and will stall when the gears are needed further down the line. That is the equivalent of a mixed belt brick problem.

So then what do we do?

We limit ourselves to 3 items per box corresponding to 3 sorters. And we give each sorter also a filter for their unique item. That way there is always a sorter available. If we only have 2 items we could even designate 2 sorters for one item and increase the transfer speed.

You will notice that all these filter settings incur a hefty editing of ingame components.But there is an “easy” way to discern and logically assign these filters for complex machines. More on that later.

I am sorry for the novel, but this is important to understand. It is not all bad I promise. The major benefits of this system will become more obvious as we delve deeper.

A practical example

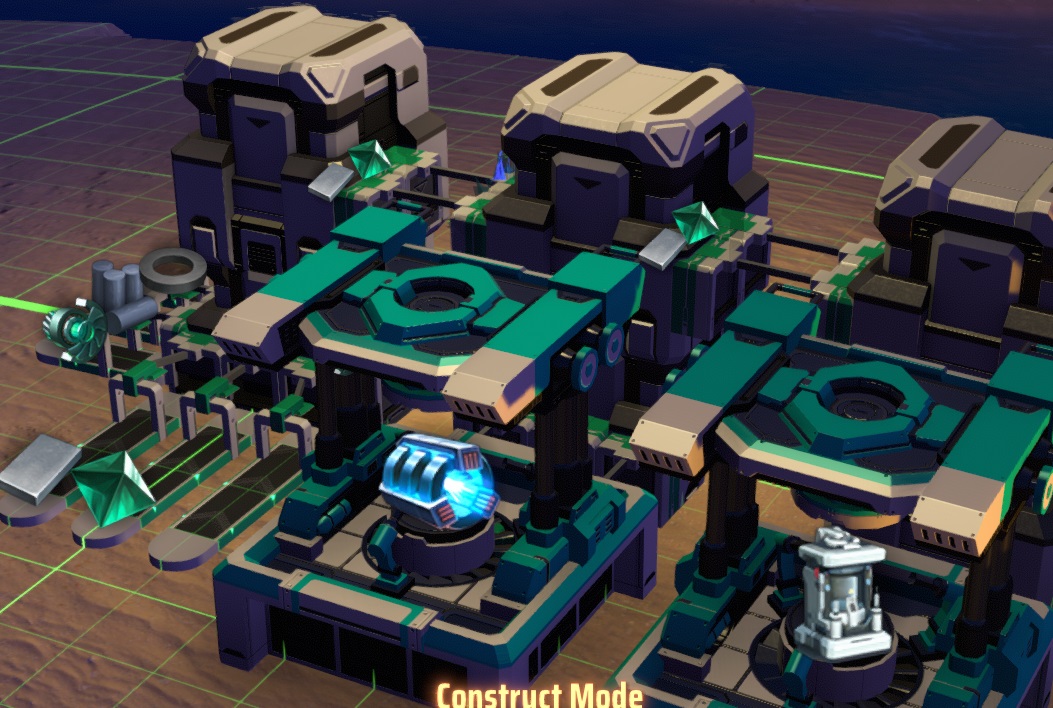

Let me try and demonstrate a small machine and the workflow behind setting filters.

Here is an assembler with a supermagnetic ring and 2 boxes. Technically only one box is needed for this, but I also want to explain the filter mechanic and what that looks like assuming there are more assemblers working in the same bus comming from the left.

The recipe is turbines, graphite and magnetic rings. The corresponding filter is set in both these boxes, as described in the previous section, we are limited to 3.

Note that the assembler itself does not have filters. And it must not have any. Because we are not using 3 sorters to put things into the assembler, we are only using two.

With the other sorter we are putting the supermagnetic ring INTO the box.

But why?

We actually don’t want supermagnetic rings we want an accumulator.

So we add the supermagnetic ring to the filters. The accumulator does not care about magnetic rings turbines or graphite.

Instead it wants green dice and iron ingots.

And thats where the verticality comes into the picture and the major advantage of this system.

We simply put boxes on top and add the inputs.

There are different methods on the input side to get items to the second level, and now you will understand why I put an extra box on the left despite only needing 3 inputs for the supermagnetic ring.

A box with 3 ports exporting has 9 ! ports for import. Together what we previously established, we know that items inserted at the bottom can also travel to the top.

In this case however it does not matter if the filter for the new items are in the bottom box of the input or in the upper one. Because we know, once the items are in the box, they can be pulled out anywhere, even from a box that has its automation disabled, as long as it is in the same pillar of boxes.

Now we add the sorters on the top, and set the filters of the boxes above and next to the supermagnetic ring assembler and the accumulator assembler to iron ingots and green dice.

This also showcases a downside of the system. Each box will want to buffer all of these items when the outputs are full. Items will keep travelling into these boxes until the stacks are full.

That is why it is important to only set one stack, and only designate one box with these filters.

There is a workaround to prevent this mayor buffering. And it comes as no surprise that it is belts.

It might not be blatantly obvious, but belts connected to boxes that are higher do not use any space as they are travelling ABOVE the assemblers.

If you understood earlier concepts you might notice something that is missing. Stop reading here and see if you can spot it. Continue reading if you think you found the mistake.

And here is what is still missing in that setup. It is filters on the sorters that take items out of the box on the right and put them onto the belt.

The same would happen as discussed with the 3 item limit and the problem of bricking the system. We must allow all present items to have a way out and assign at least one sorter to them.

This type of bypass can be very beneficial when dealing with items that are in low quantity and only used by machines further down the assembly.

Think of a raw input towards quantum chips for example. You won’t want thousands of processors building up in boxes, you want them where they are needed.

There are also other ways of bypasses.

Since we do not use any belts between assemblers or the boxes we actually have space to put some in from almost all directions unimpeded. From the side, from the direction where the input is, or the opposite side. That can come in very handy when dealing with recipes that require expensive ingredients.

A blueprint I will make available later still has this flaw where it buffers insane amounts of Strange Matter and Frame material travelling through alot of boxes without bypass despite only being needed in a single assembler.

A bypass might be ugly but it will save alot of initial ressources.

Also in this example, we would be setting the bottom box sorter just to supermagnetic ring, and the box it is travelling into where the accu assembler pulls from. It will also pull green dice and ingots from the box above the one where the supermagnetic ring will end up in.

Now you might be thinking, this is super unnecessary, and yes, for just rings into accus it would be.

What I am trying to explain is the verticality.

As you can see we simply added more ingredients of the already present one.

And this can be scaled thanks to the vertical build limit.

The limit is 8. 8 times 3 is 24. That means we can traverse a factory line with 24 different items.

That is not all. This becomes even more ridiculous when the machines progressively require more and more advanced inputs and less of basic ones.

With careful planning we can construct the ingredients with basic material early in the bus and then just phase out and switch the filters from the basic ones to the new materials. As you can do with belts that have a gap right next to an assembler pulling something in and putting something out.

But in this type you can have more that one item built of the same type and pass it along because we have more than 3 slots available to us thanks to the verticality.

Imagine what that would take for something that requires four inputs. You would have 2 belts either side and and output belt. Maybe two assemblers across each other bringing up the beltcount to 5 in the middle with 4 inputbelts and 1 output. That makes 7 belts in total with the added difficulty of sorter to grid speed if you decide to use only 3 belts in the middle, which could slow everything down when both items are og higher quantity and the sorters cannot pick up due to the grid reach slowdown.

All that is handled by the box. Do boxes use more buildings to set up? Yes and no. If you had 3 belts between 2 assemblers that makes 9 belt pieces. That becomes the box. On top of that a box build needs 3 sorters per level if you have that many different items travelling above.

I want to move on to a more simple yet elegant solution regarding a recipe requiring 5 inputs.

As it is a rare case it can be annoying to set up. As an example we have the ray receiver.

Ray receivers take supermagnetic rings, processors, steel, pure silicon and iron ingots.

We set up the iput box with just the cheap materials with corresponding filters.

Then we lay bypass belts for supermagnetic rings and cpus, because we don’t want massive amounts of those stuck in boxes buffering. The input belts are marked with icons, the assemblers have sorters connected to the boxes dragging items out and we have an output belt on the outside, because we also don’t want them buffering, and its easier to see and collect in a seperate box or tower rather than having an inventory built up in multiple boxes.

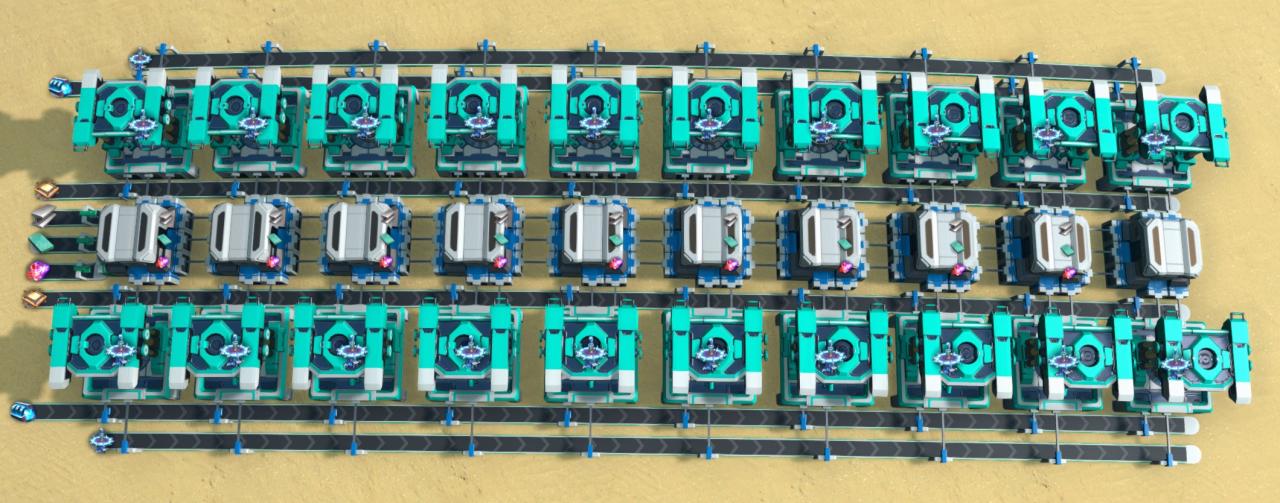

It then looks something like this.

Now it is just a matter of extending the belts and copy the boxfilter to the next box over and manually connect the sorters with filters.

And then the magic happens. As soon as that is done, the box can then be shift copied and built and it will also copy the internal filter settings and all the sorters with their filter settings between the boxes.

And the last step will be to copy construct all the assemblers.

Summary and example blueprints

There are benefits and downsides. Two major difficulties are the speed, especially when using slow sorters inbetween the boxes.

I do recommend those to be mark 3 sorters if possible. That cost can explode with rising stacks. As we uncovered we can transport 24 items across. That can make for a total of 24 mk 3 sorters. Per box tower. That is alot.

The amount of buffering is also quite considerate, and as I promised earlier let me explain a quir of this technique I have not mentioned before.

There is another priority I have not fully explored yet and I don’t know the reason for it. But it seems that items travel in a straight line first. This means that items travelling from box to box will not be pulled by any assembler that is on the way. Instead the items will reach the end first and those machines at the end will start working first.

As those are most likely the ones that need prequisites comming from further up the line closer to the input, this design can take quite some time until its fully operational. Paired with the immense buffering of a poorly constructed machine and perhaps duplicate filters which increase the buffer amount some planets factories might run hot filling up such a device.

It is good practice like with any bigger build to connect one input at a time.

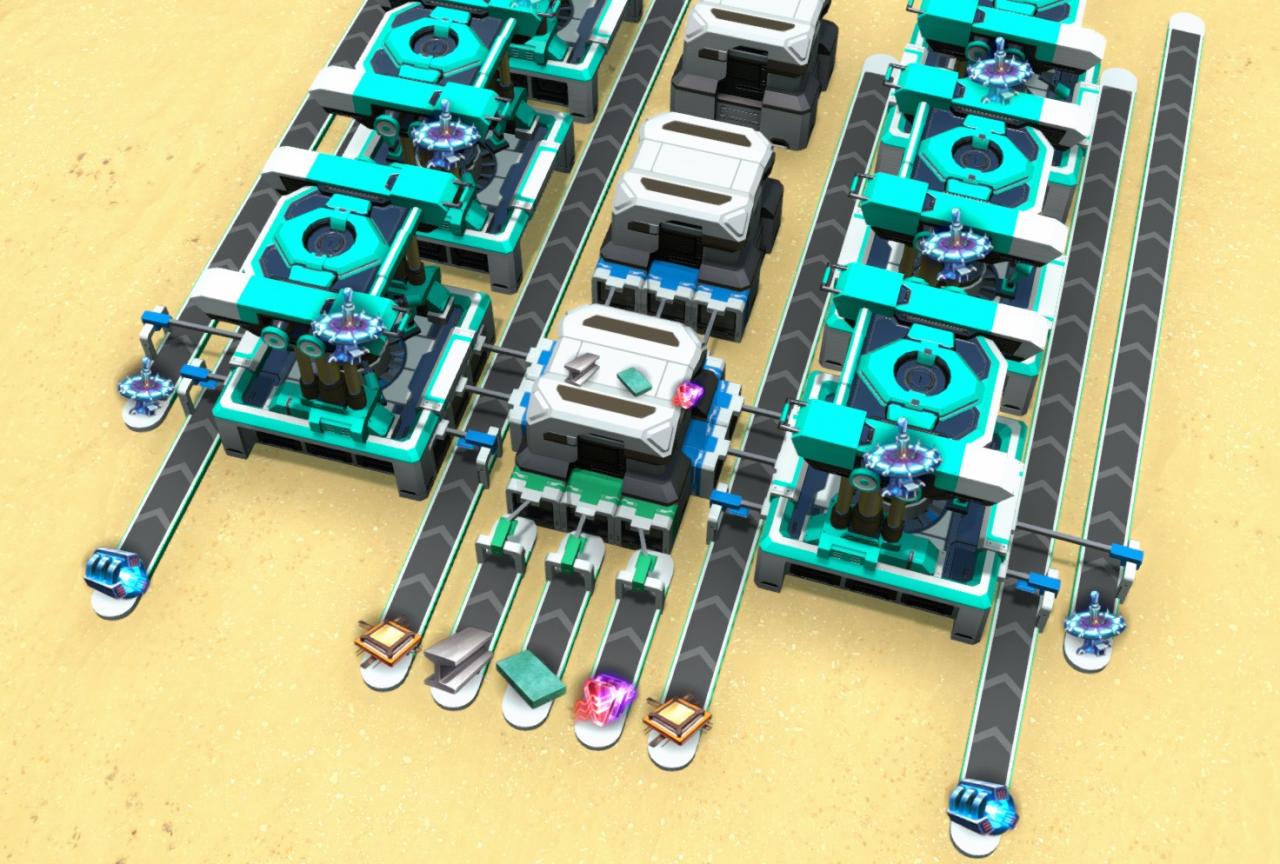

Now for the hybrid I also promised to describe. We all know and love early bus systems of long belts where you can simply take a splitter and branch something off to connect an assembler.

What if I told you that you can flip all these belts that are wide by 90 degrees. But it is even crazier. Box elevators technically have 12 inputs above 2 boxes. That means 2 boxes have 9 inputs, makes 18 and 6 boxes can have 12 inputs each. That makes 90 in total.

Although highly impractical that is the theoretic possibility of what you can make available to a single assembler. I might just build something like that as a showcase, but I am not even sure if there are 90 unique items that are used as an input.

Such an assembler would be able to build anything. All you had to do is select the recipe.

But I digress. It is maybe more practical to only use 5 inputs of the boxes. 3 on the flat side and 2 running along the box. That is still an impressive 40 inputs you can theoretically choose from.

The most space efficient design however are the ones which use the least amount of inputs per box. And that is essentially 8. So box elevators make it now possible to flip a 8 wide belt bus up 90 degrees saving alot of space. I myself built a bus with a height of 7 due to build limit using 21 belts.

It is such a hybrid, before I realised the other potentials, but its still more effective and fast than a full box system would be although using still a bigger footprint overall. But not as big as an ordinary bus would use. This hub wraps around and effectively stacks up 21 belts times 2 because I wrap around in a much smaller space.

https://www.dysonsphereblueprints.com/blueprints/factory-vertical-matrix-hub

I strongly advise you to first test it in sandbox mode, or in a map where you have fast construction drones and the new dark fog battle building to help you construct it. Read the description.

It is BIG. But not as big as something like this would take would it all lay flat.

It effectively has 54 assemblers all with unique recipes, while 2 are being used internally as prequisites. Only 3 buildings are missing from this,the launch silo, the particle collider and the orbital collector and most logistic drones and vessels. But that brings me to my other example.

A true box bus shipyard building everything, from logistics fidget spinner up to the destroyer.

As we talked about earlier, this is the build where I discovered that buffering is bad, and this BP needs to be adjusted to use bypass belts in certain locations, namely the frames and strange matter, possibly even the particle traps. But it is a thing of beauty and quite mesmerizing to watch in action. The startup time of this factory is very immense.

So is the initial material requirement. So use with caution, and remember, connect one belt at a time initially, or your factories will all run in overdrive and you might have powerproblems.

https://www.dysonsphereblueprints.com/blueprints/factory-matrix-bus-shipyard

Final note

There also is more to boxes beside being a gigantic matrix bus system, but in paces just used as a tiny elevator.

How that works you can see in this bonus blueprint. This was my first discovery and exploration of filtered boxes.

https://www.dysonsphereblueprints.com/blueprints/factory-tiny-lowtech-missile-factory

As discussed with bypasses, the room next to the box is free to use for belts. That can make for incredibly condensed builds, although you need some space for a box obviously.

I humbly applaud you if you could follow me through my explanations. English is not my native language, and I am to lazy to run all this text through a spellchecker or look for grammatical errors.

And I know that my explanations are sometimes difficult to understand when I assume something I skipped is common knowledge or a logical conclusion so bear with me.

If you have any question I will not promise to answer them, only if I feel like. Which might be never, or I could go on a typing spree. I really don’t know. I am not a content creator, nor am I aspiring, so I really don’t care if this gets any attention or not.

I also give you permission to use this guide without crediting me. I simply do not give a damn and just want to share what I have learned, and maybe it is of some use to you and makes you enjoy this game as much as I do.

Although I am a filthy casual, and my early stuff is probably the most knurled and knotted belt spaghetti you will ever see. I always rush towers.

Thank the universe for logistics towers. Also I am a space nerd, not a factory nerd. I picked this up because Dyson Spheres, not because factories. Not a fan of Factorio.

Also this advanced machine thing I have going might be because I am german. I think we have nanobots in our blood that just make us think in machine. Who knows.

Related Posts:

- Dyson Sphere Program Basic and Advanced Power & Production Math Stuff

- Dyson Sphere Program Matrix Crafting Guide (Modular Matrix Madness)

- Dyson Sphere Program Main Bus Design Guide

- Dyson Sphere Program Basic Guide for Beginner

- Dyson Sphere Program: How to Fix Troubleshooting & Crash (FAQs)